Five S (5S) methodology stands for sort, set in order, shine, standardize, and sustain. 5s is five-step methodology that creates a more organized and productive workplace.

What is 5s.

5s is a Japanese five-step methodology that creates a more organized and productive workspace. Originated as part of the Toyota Production System, the 5S method is derived from five Japanese term beginning with the letter of ”S” used to create a safe and organized workplace. 5S is a part of Lean manufacturing.

Advantage of 5s

Increases productivity.

Standardized workplace.

Reduce down time.

A safer work environment.

Reduce costs.

Greater employee satisfaction.

Sorting (Seiri)

1. Decide what is needed and to be kept.

2. Remove unnecessary clutter.

3. Remove item which are broken unusable or occasionally used.

4. When in doubt, throw it out.

5. To do this, you may want to develop a policy to fix some simple rules.

6. Team should agree to the rules and stick to them.

2. Set in order (Seiton)

After sorting, next step is to organize and arrange the remaining essential items to promote efficiency and easy access. Item should be labelled and store in designated locations.

1. Arranging tools, equipment and materials with clear and defined marking so that they will be easy to find and readily available when needed.

2. Tools etc. should be close to where they are needed.

3. Shadow boards are often used.

4. Outlining work areas and location.

5. Installing modular shelving and cabinets.

3. Shine (Seiso)

Shine emphasizes on the need to keep the workplace clean and neat, after the clutter in the work areas are eliminated and remaining items are organized. Everyone thinks they know what housekeeping is, but it’s one of easiest things to overlook, especially when work get busy. The shine stage of 5s focuses on cleaning up the work area, which means businesses can catch problems and prevent breakdown.

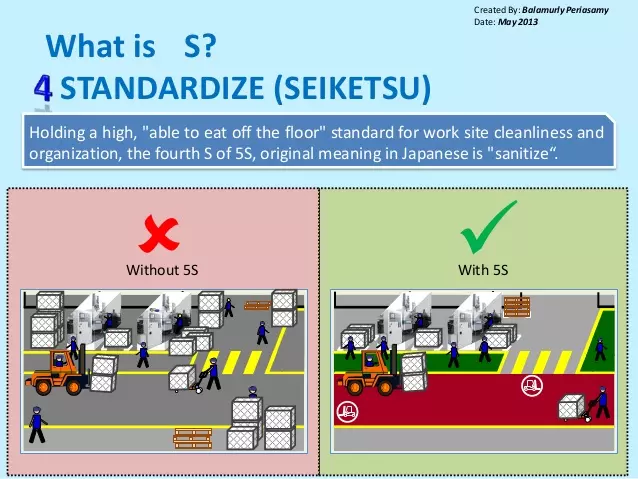

4. Standardize (Shitsuke)

Once the first three steps of 5s mythology are completed, things should look pretty good. All the extra stuff is gone, everything is organized, space are cleaned, and equipment is in good working order

5. Sustain (Shitsuke)