If you want to know about what is Blown film then this article is for you. his technical brochure covers some of the most common blown film problems and their probable solutions. It is hoped that the information contained here will be of assistance to you.

What is blown film?

Blown film is a type of plastic film made by extruding molten polymer through a circular die, then inflating it like a balloon. As the film rises, it cools and solidifies, creating a thin, continuous tube of plastic that can be flattened and wound into rolls.

This method is one of the most popular ways to manufacture flexible plastic films for packaging, agriculture, and industrial use. You’ve likely encountered blown film in grocery bags, food packaging, shrink wraps, and even construction sheeting.

How does blown film work- Explain step by step

In this process we extrude the material through single screw extruder then melt material

1. Feeding and Melting the Polymer

It all begins with plastic resin pellets, often polyethylene (like LDPE, LLDPE, or HDPE), fed into a hopper. These pellets are then pushed through an extruder—a long, heated barrel with a rotating screw.

As the screw turns, it heats and melts the plastic, creating a uniform molten polymer ready for shaping.

2. Extrusion Through the Die

Next, the molten plastic is forced through a circular die, which shapes it into a tube. This is the starting point for the film.

The diameter of the die and the speed of extrusion help determine the film’s initial size.

3. Blowing the Bubble

Here’s where the magic happens.

Air is blown into the center of the tube, causing it to inflate like a balloon. This bubble stretches the plastic in both the vertical and horizontal directions, giving the film strength and flexibility.

The ratio of the bubble’s size to the die’s diameter is called the blow-up ratio, a key factor in controlling the film’s properties.

4. Cooling the Film

As the bubble rises, it passes through a cooling ring that blows chilled air onto the surface. This step helps solidify the plastic while maintaining its shape.

In some systems, additional air rings or chillers are used for faster cooling and better film clarity.

5. Flattening and Winding

At the top of the bubble, it enters a set of rollers called the nip rollers, which flatten the film into a double layer.

The flattened film—now called a layflat tube—is wound onto large rolls and later slit, folded, or printed depending on the final application.

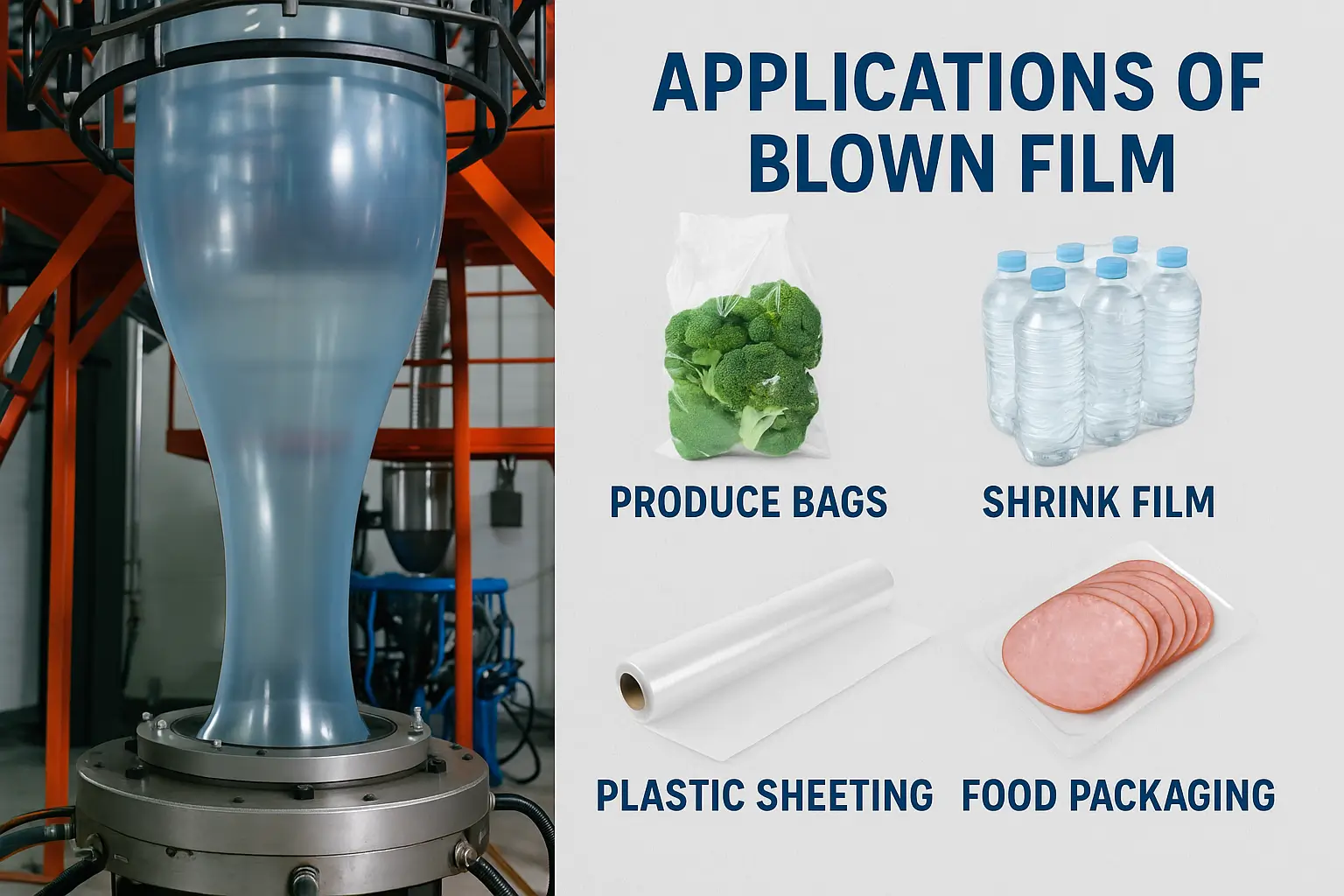

Application of blown film

Plastic bags (grocery bags, trash liners, zip-lock bags)

- Food packaging (snack pouches, frozen food wraps)

- Shrink film and stretch film

- Agricultural films (mulch film, greenhouse film)

- Construction sheeting (vapor barriers, protective covers)

- Cosmetic packaging (Creem tube, powder, gel)

- Pharmaceutical sector (tablet outer packaging)

Because the process allows for precise control over thickness and material composition, it’s ideal for making both single-layer and multi-layer films with tailored properties like strength, barrier resistance, and flexibility.

Blown film vs cast film

| Features | Blown film | Cast film |

| Equipment Cost | Cheap project | Expensive project |

| Strength | Low tensile strength | Excellent tensile strength |

| Clarity | Medium clarity | High clarity |

| Cooling method | Air cooled | Roller cooled |

| Production | Moderate | Faster |

| Gauge control | Moderate | excellence |

| Printability | Moderate | excellent visibility |

Advantages of the Blown Film Process

So, what makes blown film so popular in the plastic industry?

✅ Cost-Effective

Blown film equipment is relatively affordable, and the process is efficient, making it ideal for high-volume production.

✅ Versatility

From thick industrial sheeting to ultra-thin packaging films, blown film can be customized for a wide range of applications.

✅ Strength and Uniformity

The biaxial orientation during the blowing process gives the film balanced strength, making it less prone to tearing.

✅ Multi-Layer Capabilities

Modern machines can co-extrude multiple layers in a single film—adding features like moisture barriers, UV resistance, or color tinting.

Challenges and Limitations

Of course, no process is perfect. Blown film does come with some limitations:

⚠️ Lower Optical Clarity

Compared to cast film, blown film may have more haze or cloudiness, depending on the material and cooling method.

⚠️ Slower Cooling Time

Because the film is cooled by air rather than chilled rollers, it may take longer to set, reducing overall speed.

⚠️ Difficult to Handle Thin Films

Making ultra-thin films can be tricky and requires precise control over pressure, temperature, and cooling.

Final Thoughts: Why Blown Film Matters

Blown film may seem like a niche manufacturing technique, but its impact is everywhere. From packaging your lunch to protecting crops in a field, blown film plays a vital role in modern life.

By understanding the blown film process, you’re not only gaining insight into a key industrial technology—you’re also appreciating the engineering behind the plastic products we use every day.

Whether you’re in manufacturing, product development, or sustainability, knowing how blown film works can help you make smarter decisions about materials, processes, and end-use applications.

Frequently Asked Questions (FAQs)

What materials are used in blown film?

Common materials include LDPE (Low-Density Polyethylene), LLDPE (Linear Low-Density PE), HDPE (High-Density PE), and various co-polymers depending on desired properties.

Can blown film be recycled?

Yes! Most blown films made from mono-materials like polyethylene are recyclable. Multi-layer films may be harder to recycle, but advances in technology are helping improve that.

How thick can blown film be made?

Typical thicknesses range from 10 to 200 microns, though special films can go beyond that range based on application.

Can we print in blown film materials?

Yes, we can easily print in blown film, because during processing of blown film we give a corona treatment to improve surface properties, which is required for printing and lamination.