In today’s environmentally conscious world, businesses are increasingly seeking sustainable packaging solutions that do not compromise on performance. Machine Direction Oriented (MDO) Film has emerged as a leading choice in this regard. let us we will understand Benefits of MDO Film & how can MDO film revolutionaries packaging industries.

What Is MDO Film?

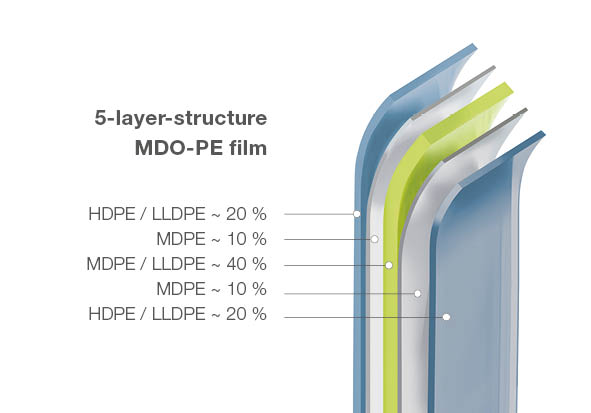

MDO film is produced by stretching polyethylene film in the machine direction, just below its melting point, using rollers and heat. This orientation process aligns the polymer chains, resulting in a film that is thinner, stronger, and more durable than conventional polyethylene films. The outcome is a lightweight yet robust material suitable for various packaging applications.

Key Benefits of MDO Film

1. Enhanced Strength and Durability

The stretching process significantly increases the tensile strength and tear resistance of MDO film. This enhancement makes the film more durable and less prone to damage during handling and transportation, ensuring that packaged products remain intact and secure.

2. Lightweight and Cost-Effective

MDO film is thinner than traditional films, reducing material usage and lowering production costs. Its lightweight nature also leads to decreased transportation expenses, as more products can be shipped per load, contributing to overall cost savings and reduced carbon emissions. MDO film is thinner than traditional films, reducing material usage and lowering production costs. Its lightweight nature also leads to decreased transportation expenses, as more products can be shipped per load, contributing to overall cost savings and reduced carbon emissions.

3. Superior Optical Clarity

The orientation process improves the optical properties of MDO film, resulting in higher transparency and gloss. This clarity enhances product visibility on store shelves, making it more appealing to consumers and potentially increasing sales

4. Excellent Barrier Properties

MDO film exhibits improved resistance to moisture, oxygen, and other environmental factors. This makes it an ideal choice for packaging products that require protection from external elements, thereby extending shelf life and maintaining product quality.

5. Recyclable and Environmentally Friendly

As a mono-material film, MDO PE is fully recyclable, aligning with global sustainability goals. Its recyclability reduces the environmental impact associated with packaging waste and supports a circular economy approach to packaging .

Applications of MDO Film

MDO film’s versatility allows it to be used across various industries:

- Food and Beverage: Its moisture resistance and clarity make it suitable for packaging

- Consumer Goods: MDO film is used for packaging items like pet food, detergents, and personal care products, offering durability and visual appeal.

- Hygiene Products: The film’s strength and barrier properties are ideal for packaging diapers, sanitary products, and wet wipes, snacks, dairy products, and beverages.

- Medical and Pharmaceutical: Its puncture resistance and tamper-evident capabilities make it suitable for packaging medical supplies and pharmaceuticals .

Characteristics of MDO film

- Good tensile strength

- Good glossy

- Easy tear in MD direction

- High barrier properties

- Good dimensional stability

- Good puncture resistance

- Excellent printability

- High rigidity

Why packaging industries shift towards MDO film

MDO film is mostly use because its 100 % recycle and mono material. we can use as polyester film . It can be replace the polyester film and make MDO PE / PE instead of PET/PE structure to achieve sustainable through recyclability. Because PET/PE is complex to easily recycle. MDO film has good barrier properties so we can replace PET/METPET/ PE structure into MDO/PE.

Conclusion

MDO film represents a significant advancement in packaging technology, offering a sustainable, cost-effective, and high-performance solution for various industries. Its enhanced strength, optical clarity, and recyclability make it a preferred choice for businesses aiming to meet environmental standards without compromising on product quality. By adopting MDO film, companies can contribute to a more sustainable future while delivering superior packaging solutions to their customers.