Flexible packaging has become the backbone of modern industries like food, pharmaceuticals, and personal care. Among the wide range of films available, PET (Polyester), BOPP (Biaxially Oriented Polypropylene), and Nylon (Polyamide) are the most widely used for barrier applications. But choosing the right one isn’t always straightforward. Each film offers unique strengths and limitations that can directly impact product protection, shelf life, and cost-effectiveness.

In this guide, we’ll break down the key differences between PET, BOPP, and Nylon films and help you decide which option works best for your packaging needs.

Why Barrier Properties Matter in Flexible Packaging

Barrier properties refer to a film’s ability to block oxygen, moisture, aroma, grease, and light from entering or escaping the package. These characteristics are crucial because they:

- Extend product shelf life

- Preserve flavor, aroma, and texture

- Ensure food safety and freshness

- Prevent contamination or spoilage

- Support sustainability by reducing waste

Now, let’s explore how PET, BOPP, and Nylon perform in these critical areas.

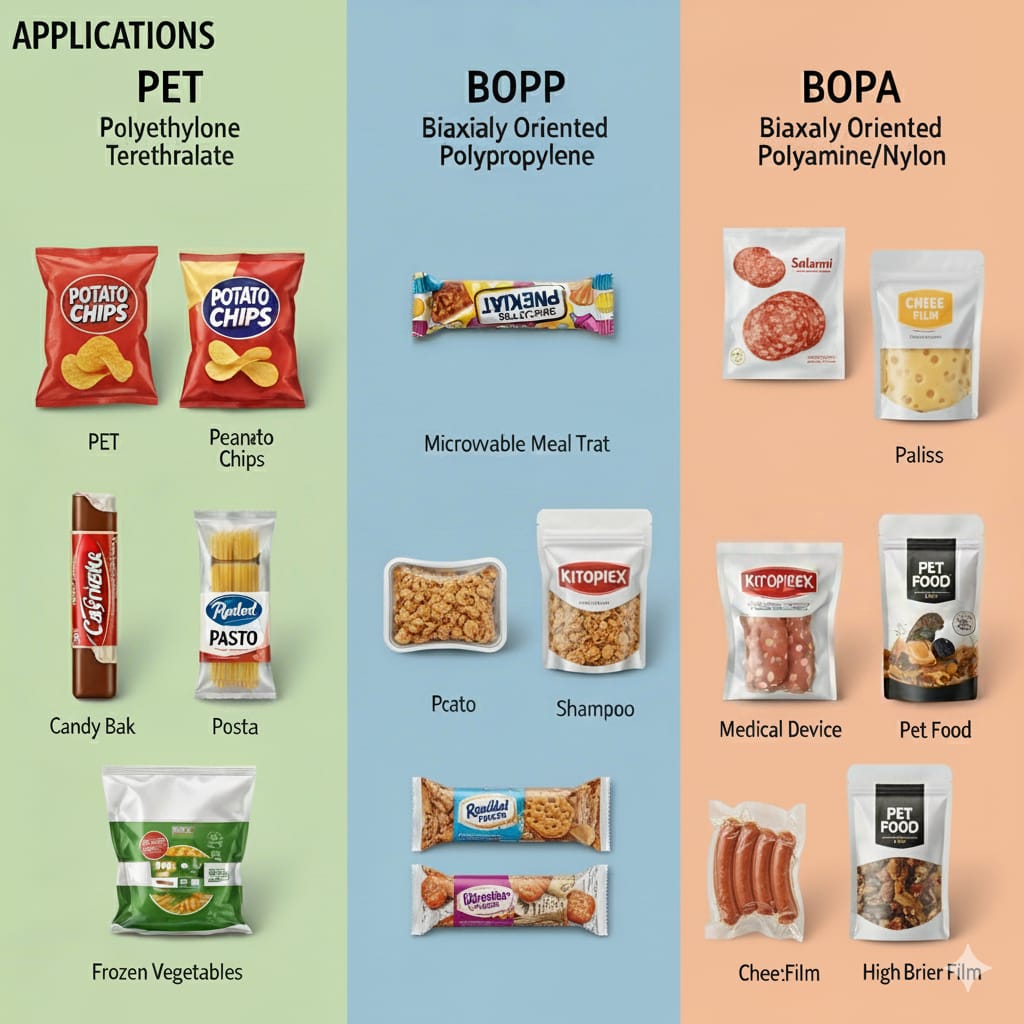

PET Films: The Reliable All-Rounder

Polyethylene Terephthalate (PET) is one of the most popular films used in flexible packaging.

Key Strengths of PET

- Excellent dimensional stability – PET films don’t shrink or stretch easily, making them ideal for high-speed printing and lamination.

- High oxygen barrier – Great for preserving dry snacks, coffee, and powdered foods.

- Superior clarity and gloss – Enhances shelf appeal with vibrant print and transparency.

- Good heat resistance – Works well in retort and hot-fill packaging.

Limitations of PET

- Moderate moisture barrier – PET is not as strong against water vapor, so it usually needs to be laminated with films like PE or aluminum foil.

- Cost – Slightly higher than BOPP, which may matter for cost-sensitive products.

👉 Best suited for: Chips, biscuits, powdered drinks, spices, and products needing strong oxygen barrier with high print quality

BOPP Films: The Cost-Effective Performer

Biaxially Oriented Polypropylene (BOPP) is another widely used film known for its versatility and affordability.

Key Strengths of BOPP

- Excellent moisture barrier – Ideal for products that are sensitive to humidity.

- Lightweight and economical – Lower density compared to PET, giving more yield per kilogram.

- Good clarity and printability – Suitable for attractive packaging designs.

- Wide seal range – Allows easy sealing for pouches and wraps.

- Softness – Bopp is known for softness. It provides sound less, soft as compared to PE film.

- Sustainable– Bopp film is easily recycled with CPP, LDPE which is sustainable option for customer.

- Easy tear- Bopp film is better option for easy tear application such as Biscuits, Chocolate, Ice cream Etc.

Limitations of BOPP

- Poor oxygen barrier – Needs to be laminated with PET, Nylon, or metallized layers for oxygen-sensitive products.

- Lower heat resistance – Not suitable for retort or hot-fill applications.

- Poor bonding with LDPE film – BOPP is Not suitable for lamination with LDPE film.

👉 Best suited for: Bakery items, confectionery, dry fruits, noodles, and snack packaging where moisture protection is the priority.

Nylon Films: The Strong Specialist

Nylon, also called Polyamide (PA), is less common than PET and BOPP but shines in specific applications where strength and toughness are critical.

Key Strengths of Nylon

- Outstanding puncture and abrasion resistance – Perfect for sharp or irregularly shaped products.

- Excellent oxygen barrier – Comparable to PET, making it suitable for vacuum packaging.

- High temperature resistance – Performs well in boil-in-bag or retort pouches.

- Good flexibility – Maintains performance under stress and pressure.

Limitations of Nylon

- Poor moisture barrier – Absorbs water, which can compromise barrier performance.

- Higher cost – More expensive than both PET and BOPP.

- Limited availability – Not as widely stocked as PET or BOPP in some markets.

👉 Best suited for: Meat, cheese, frozen food, liquid packaging, and products needing puncture resistance.

Side-by-Side Comparison: PET vs BOPP vs Nylon

| Property | PET Film | BOPP Film | Nylon Film |

| Oxygen Barrier | High | Low | High |

| Moisture Barrier | Moderate | Excellent | Poor |

| Clarity & Gloss | Excellent | Good | Moderate |

| Strength & Puncture | Moderate | Low | Excellent |

| Heat Resistance | High | Low | High |

| Cost | Medium | Low | High |

| Best Use | Snacks, powders | Bakery, dry foods | Meat, frozen food, oil |

How to Choose the Right Film for Your Packaging

When selecting between PET, BOPP, and Nylon, consider these key factors:

1. Product Sensitivity

- If your product is oxygen-sensitive (coffee, spices, chips) → PET or Nylon is better.

- If your product is moisture-sensitive (biscuits, dry fruits, noodles) → BOPP is the top choice.

2. Shelf-Life Requirements

- For long shelf life with strong aroma retention → Use PET/Nylon with barrier layers.

- For shorter shelf life and cost efficiency → BOPP-based structures work well.

3. Packaging Process

- High-temperature processes like retort → PET or Nylon.

- Standard pouches and flow wraps → BOPP.

4. Mechanical Needs

- Sharp or heavy products → Nylon’s toughness prevents punctures.

- Lightweight snacks → BOPP or PET laminates are sufficient.

5. Budget

- Cost-sensitive products → BOPP offers the best economy.

- Premium or critical applications → PET or Nylon ensures better protection.

Final Thoughts

Choosing between PET, BOPP, and Nylon films depends on balancing performance, cost, and product requirements. PET provides excellent oxygen barrier and prints quality, making it a versatile option. BOPP is the most economical with a strong moisture barrier, perfect for bakery and snack products. Nylon stands out for its toughness and high oxygen barrier, ideal for meat, cheese, and retort packaging.

In most cases, these films are not used alone but combined in laminated structures to deliver the best of each property. For example:

- PET/PE for snacks

- BOPP/CPP for biscuits

- Nylon/PE for meat packaging

What is the difference between pet & bopp.

PET (Polyester) and BOPP (Biaxially Oriented Polypropylene) films are both popular in flexible packaging, but they serve different purposes. PET film has higher strength, stiffness, and excellent heat resistance, making it ideal for high-temperature applications, print quality, and barrier performance. On the other hand, BOPP film is lighter, more cost-effective, and offers good moisture resistance along with high clarity, which is why it is commonly used in snack, bakery, and label packaging. In short, PET is chosen for durability and heat stability, while BOPP is preferred for cost-efficiency and moisture protection.

Is boPET better than BOPP

BoPET (biaxially oriented polyester) and BOPP (biaxially oriented polypropylene) are designed for different strengths, so one is not universally “better” than the other. BoPET offers superior tensile strength, dimensional stability, and excellent barrier properties against gases and aromas, which makes it ideal for applications like high-quality printing, lamination, and products requiring long shelf life. BOPP, however, is more economical, provides excellent moisture resistance, and delivers great clarity and gloss, making it the preferred choice for snacks, confectionery, and everyday consumer packaging. The “better” option depends on the packaging need—choose BoPET for durability and performance, and BOPP for cost-effectiveness and moisture protection.